We're now part of Nactarome, your partner for natural flavour, taste & colour solutions. Learn more

How it's made

A unique process delivering unique product

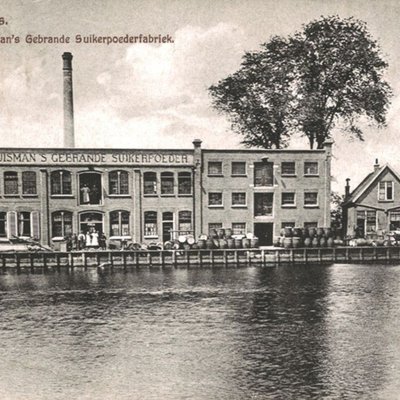

Since the foundation of Royal Buisman in 1867, we have specialised in the caramelisation of sugars. Since then, the process has evolved to meet the highest standards and expectations of our customers.

5 steps

Our unique process consists of the following steps.

- We carefully select ingredients

- We heat the sugars intensively, in a strictly controlled manner

- We cool the hot mass on a cooling plate

- We crush and grind the cured caramelised sugars to a powder

- We package the products

Ingredients

We use different types of sugar: beet sugar, glucose syrup and molasses. Each type provides a different flavour.

Heating process

A solution of sugars is added to a specially designed vat that allows for controlled heat treatment. Intense heat causes the sugar molecules to break down, starting a chain reaction that forms a rich mixture of aromatic compounds – a very delicate process that is similar to the roasting of coffee beans. Different combinations of sugars and processing conditions allow us to create unique flavour profiles.

Cooling, breaking and grinding

Once the desired composition has been reached, the caramelised sugars are loaded onto a large cooling plate. The highly viscous and hot mass is then spread in a thin layer. When the mass cools, the caramelised sugar becomes hard like glass. The hardened caramelised sugar is then broken into smaller pieces and ground into an easy-to-use fine, dark brown powder.

Packaging

The caramelised sugar in powder form is then packaged or used to make a product in liquid form. Both products are pure caramelised sugars – free of carriers such as maltodextrin.